The Victoria Falls Bridge

Spectacular views from the bridge towards the boiling pot as the Zambezi River surges down the first gorge.

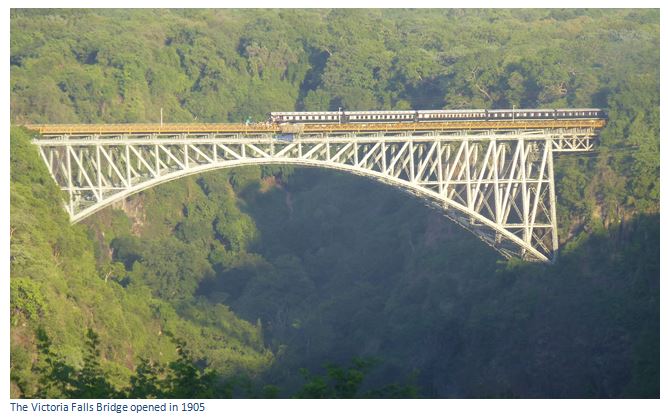

Constructing the bridge was a remarkable achievement in 1904-5 which required great organisational ability to bring all the materials from the UK and assemble the engineering team in this spot where wild animals still roamed. At the time it was the highest bridge above water level in the world.

Construction took 14 months and the final join was done at dawn because the sun’s heat the previous day had caused the steel trusses to expand about 1¼ inches (3.2 cm), but at dawn they fitted perfectly.

As for Victoria Falls

GPS reference: 17⁰55′40.01″S 25⁰51′24.15″E

Percy Clark in his book Autobiography of an Old Drifter tells how Charles Fox, nephew of Sir Douglas Fox, whose firm was responsible for much of the design of the railway systems throughout southern Africa, arrived in the New Year of 1904 to begin the foundations for the bridge. This entailed getting down to the bedrock halfway down the gorge to support the bridge’s abutments at both the southern and northern banks where the superstructure of the single arch span would rest.

At this time the railway line was still a hundred kilometres away, but steadily approaching.

Design and engineering

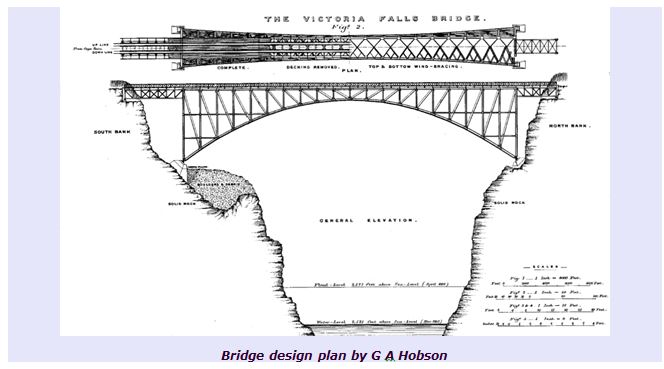

The main credit for designing the Victoria Falls Bridge goes to George Andrew Hobson of Douglas Fox and Partners, later to become Freeman, Fox and Partners. Hobson, in his final report on the construction of the bridge to the British Institute of Civil Engineers in 1907, records that in 1901, while in London, Rhodes was shown a sketch of the bridge as it was then proposed to be built.

Although he had never visited the locality, he was sufficiently familiar with it from travellers' descriptions and engineers' surveys to indicate in a general way the point of crossing. He determined that passengers in the trains going over the bridge should have a view of the Falls; and as the site on which the bridge now stands is practically the only one which could fulfil this purpose, it may be said to have been chosen by him. The preliminary design of the bridge above referred to was prepared to meet Mr. Rhodes's views, and it received his approval. [Hobson, 1907]

Hobson summarised the technical specifications of the bridge:

The bridge consists of three spans. The end span on the left bank of the river is 62 feet 6 inches, and that on the other bank 87 feet 6 inches. These spans are composed of braced girders of ordinary type, 12 feet 6 inches deep, with horizontal upper and lower chords, and divided into square panels. The girders are fixed 20 feet apart. Connected with the end posts of the central span, they unite it with each bank of the river in a direct and simple manner. The deck is horizontal, and is laid on the top chords throughout the bridge... The cross girders, spaced 12 feet 6 inches apart, rest on the top chord.

"The central span is 500 feet from centre to centre of bearings, with a rise of 90 feet. The curvature of the arched rib is parabolic. The panels, twenty in number, are 25 feet in length. The depth of the girder at the crown is 15 feet, and at the abutment 105 feet. Each main girder stands in a plane at an inclination of 1 in 8 from the perpendicular. The width between the centres of the girders is 27 feet 6 inches at the top, and 53 feet 9 inches at the springing level, and the width between the parapets 30 feet. There is a camber of 9 inches in the top chord. [Hobson, 1907]

The bridge is known as a trussed arch design. Each section was to be built outwards towards the centre from the sides of the gorge. As work progressed, these half spans were supported as cantilevers by steel wire cables running through galleries cut into the rock on either bank.

The Contract for the bridge

Tenders were invited from contractors, about which Hobson states: "In designing the details consideration had also to be given to the available means of transport by sea and rail, and particularly to the fact that the parts for one-half of the bridge would have to be conveyed across the great chasm by means of some temporary expedient.

The contract was divided into two parts, namely, first, the construction of the steelwork in the makers' yard and the delivery of it on board ship in a British port; and secondly, the erection of the steelwork on the site. Tenders were invited from British, American, and German firms-the majority of whom ventured only to quote a price for the first part of the work."

In the end, only two firms, Dorman, Long & Co. and the Cleveland Bridge & Engineering Company of Darlington, were in the running. The railway contractors, Pauling & Co, also tendered for the contract and George Pauling was disappointed to lose the contract, but contented himself with the belief that the winning bid was too low, and that there was little profit to be gained. He wrote in his autobiography 'Chronicles of a Contractor': "My firm had sent in a tender but it was too high; their tender, on the other hand, was too low, and I hardly think they made a profit on the work. I had had so great a connection with railway work in Rhodesia that I was sorry we had not the honour of building the bridge, but honour of that kind can be purchased at too heavy a price." [Pauling, 1926]

In May 1903 both parts of the contract were awarded to The Cleveland Bridge Company, to construct and erect the Victoria Falls Bridge for a price of £72,000. The company was also destined, thirty years later, to build another bridge across the Zambezi, the Lower Zambezi Bridge at Sena, Mozambique, with a total length of two and three quarter miles (4.4 kilometres)

The contract was allocated as follows :-

Steelwork £21,000

Transport £12,700

Erection £27,000

Cableway £4,000

Spare rope, conveyor and tires £750

Excavations, exclusive of railway cutting £6,550

Total £72,000

Hobson writes: It was then anticipated that the construction of the railway up to the Falls would be completed by the end of that year or the beginning of the next, but unexpected difficulties were met with on the route, which caused a delay of 4 months. The rail-head actually reached the site at the end of May, 1904. Until then the transportation of the bridge-material was impossible. [Hobson, 1907]

Pre- Construction at site

Georges Imbault was appointed as Chief Construction Engineer for the Cleveland Bridge Company on site. He travelled out by ship to Cape Town and then by rail to Bulawayo, where he was joined by Sir Charles Metcalfe and Stephen Townsend, Resident Engineer for Rhodesia Railways, and together they travelled on to the Victoria Falls. At this time the construction of the railway was still more than one hundred miles short from its destination and they had a rough trek overland to complete their journey and so it was only on 2 September, 1903, that Imbault viewed the site for the first time.

A construction yard was established on the south bank, where all bridge materials were stored. A temporary camp for the bridge construction engineers was set in early 1904 about a kilometre from the construction yard, on the south side of the old track leading to Clark's Ferry, and named Tower's Camp. William Tower was chief assistant engineer to Townsend and he was Resident Engineer for the construction of the bridge. His assistants at the start of the works were Mr C Everard and Beresford Fox.

Beresford Fox oversaw construction of the camp and put up fifteen to twenty huts for the benefit of the railway and bridge construction workers. Another camp was later established on the Zambian bank of the Zambezi, known varyingly as Imbault's, or Salmon's (one of the railway surveyors) camp.

Before its construction it was necessary to either make a journey of thirteen kilometres to the Old Drift and cross the river by ferry, or cross the river by canoe above the Falls at Giese's Drift, just above the Devil's Cataract on the south side of the river to Maramba Drift on the northern bank, and then back down to the bridge site, a distance of five kilometres.

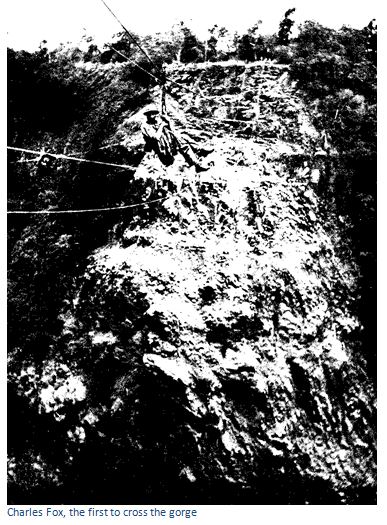

The ravine was bridged by firing a rocket with a thin string attached from one bank to the other which was hauled across pulling after it a thicker cord, then a rope, and finally a steel cable was hauled across. A bosun’s chair was strung to the cable, which then moved engineers across the ravine taking ten minutes to cross.

Percy Clark describes the first attempt as a failure as the rocket fell short, but the third attempt succeeded.

This was downstream, a few yards from the bridge site, and this small cable system successfully transported small loads, tools and even people throughout the building of the bridge. A telephone line was also established across the gorge for effective communication.

Clark took the above photograph of Charles Fox, nephew of the Bridge designer, Sir Douglas Fox, who was the first to cross the gorge in a bosun’s chair. Clark says that the first time he went across; seated on a small plank like the seat of a child’s swing and with my legs in a sack, I was very much aware of the tumult and surge of the torrent 400 feet below, and I felt anything but happy. It was a trial to the strongest nerves to be suspended, with only a rope to cling to above those boiling rapids. I was the fourth man to cross the gorge.

With the railway approaching the Victoria Falls, heavy construction materials could at last be transported to the bridge site and Imbault's next task was the installation of a more powerful cable system to transport the large volume of building materials needed to the north bank.

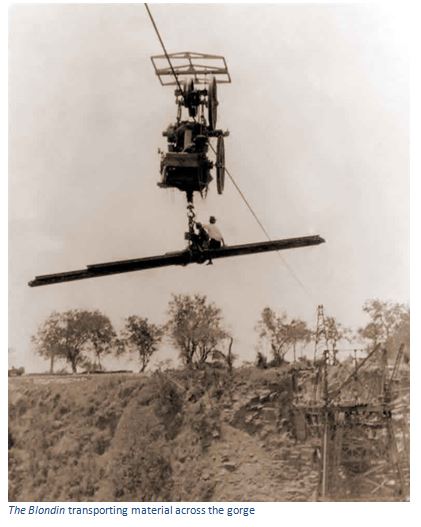

The Blondin

Hobson recalls: In July, 1903, tenders had been invited for a cableway to span a distance of 870 feet [265 metres] and carry a load of 10 tons net. The conveyor was specified to be capable of lifting and lowering as well as travelling with this load, and to be operated by means of electricity.

Situated on the upstream side of the bridge, the apparatus was installed and in working order by the 28th July 1904. The electronic transporter system became known as ‘the Blondin’ after the daredevil tightrope walker Charles Blondin who had famously crossed the Niagara Falls by rope in 1859. Electricity came from a portable steam-driven engine and dynamo which was located near the construction yard on the south bank. In addition to transporting half of the steelwork for the bridge across the gorge, over 40 miles of track materials were also transported using the Blondin. This allowed the railway construction gangs to continue the development of the railway line north before the bridge itself was completed.

The most hazardous task was getting the 19 ton 'Jack Tar' locomotive onto the north side of the Zambezi whilst the bridge was being completed. She was dismantled and transported over the gorge piece by piece by means of the Blondin cableway, the boiler and lighter parts sent over first. The body frame and cylinders weighed twelve tons and had to be transported in one piece. Visitors present said the cable sagged fourteen metres under this load and hung over the gorge for three hours as the Blondin's engine struggled to cope with its weight; eventually managing to pull itself to the other side.

Built in 1889 by Manning Wardle & Co of Leeds, Yorkshire, the Jack Tar was purchased by Pauling & Co, the railway construction contractors, in 1896 and shipped to Beira before assembly at Umtali (now Mutare) where it was used on the widening of the Beira railway, before being transferred to Victoria Falls in 1904-1905.

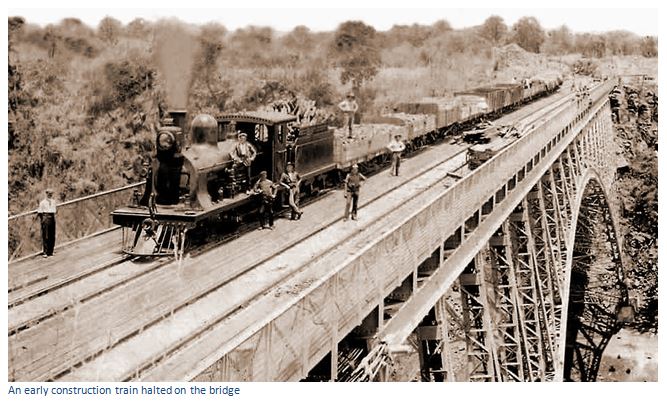

The Jack Tar pulled the first train in Zambia, over a short two mile track built in a day by the railway construction workers and was the first locomotive engine to cross the completed Victoria Falls bridge, although the official first train service was only on the official opening several months later.

After the bridge was finished the Jack Tar returned to Beira for light shunting duties before being transferred to Bulawayo in 1927. In 1935, in addition to reboilering, a brass dome and cap to the chimney were added and a new fully enclosed cab was fitted in place of the original open shelter. The black livery was replaced with dark green, lined with yellow. Today the fully restored locomotive is a star attraction at the National Railways Museum at Bulawayo.

Start of construction

The project was significantly delayed because the south side had no solid foundation rock until a depth of about 15 metres was reached. Hobson (1907) records: "The mistake was perhaps excusable, and was not discovered until the vegetation which thrives in the hot sun and the spray from the falls had been removed, and the work of clearing the ground and the excavation of the rock had proceeded for some time. It was then found that the shelf on the right bank on which it was intended to rest one end of the principal span was covered to a considerable depth with debris. By the time the error had been discovered, the preparation of the steelwork was too far advanced to permit of any alteration being made in the structure. The difficulty had therefore to be overcome partly by increasing the depth of the concrete foundations, and partly by lowering the level of the entire bridge to the extent of 21 feet; but both time and money would have been saved had the true facts of the case been recognized at the beginning, the span designed 25 feet longer, and the truss increased in depth at the ends by 20 feet." [Hobson, 1907]

Owing to the lowering of the bridge by 21 feet (6.4 metres) the line had to run in a cutting on each side of the gorge, and not, as had been planned, at the same level of the Falls. "The size of the excavation on the left bank was small, the rock there being sound, but its position on the face of an almost perpendicular cliff rendered work slow and dangerous. On the right bank it was more easily accessible, but was considerably larger owing to the burden of debris which had to be removed. “[Hobson, 1907]

The specification for the concrete work was rigidly enforced with all concrete was mixed on the foundation site on the south bank, and transported to the north bank in batches. Any batch not placed in position within 20 minutes after mixing was discarded into the gorge.

Varian describes the work: "All materials for the foundations had to be lowered from the Blondin at both ends. A steel bucket, four feet in diameter and four feet deep, carried all materials such as sand, cement and water. Visiting that part of the work was another unpleasant little trip. By the time the bucket was lowered to the requisite depth, on some 150 feet of single rope, it had an unsettling trick of revolving violently one way, then stopping, and revolving with equal violence in the opposite direction." [Varian, 1953]

Work started in May and the concrete foundations for the bridge were finally ready in October 1904. The anchorages for supporting the main span during its cantilever stage were then prepared, with the erection of the end posts and the two side spans of the bridge, supported on the abutments and anchored to the rock behind by steel cables, were completed in late December 1904.

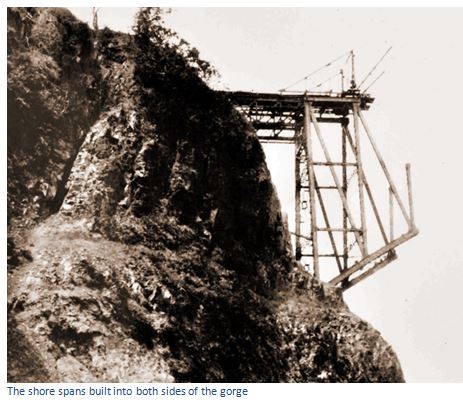

Erection of the side spans proved to be one of the biggest challenges in construction. Hobson records:

"The really difficult and risky part of the work of erection lay in the end spans, which now look so small as compared with the arch itself that they are scarcely noticed. But once the tall end posts of the main arch were erected, and the short spans were connected with them and the shore, thus affording a stable platform to start from, the rest was easy and rapid work. This stage was actually reached during the last days of 1904." [Hobson, 1923]

Hobson (1907) continues: "The work of erecting the steelwork actually began in August, 1904, and the most difficult and slowest part of it proved to be the operations of fixing the shore spans and connecting them with the end posts of the main girders. The ends of the shore spans were let into recesses cut out of the rock and anchored by their upper corners. They were built out a certain distance as cantilevers, and at a further stage supported by scaffolding fixed on the slope of the cliff. As soon as the end post of the main span was up, the shore span connected with it and the anchorage coupled, a stable platform was obtained and the rest was easy and expeditious work. “[Hobson, 1907]

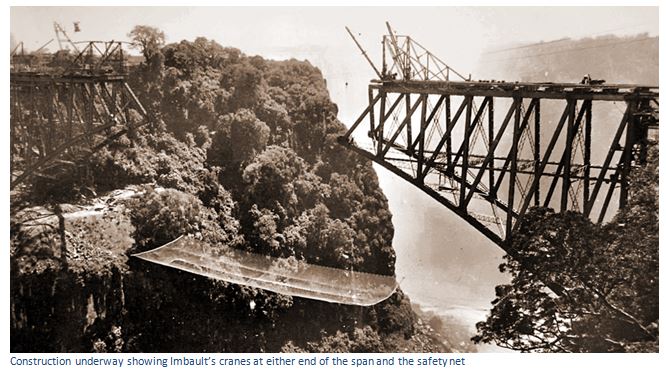

Once the shore spans were completed, the building of the main arch progressed rapidly. The arch was erected simultaneously from either side as two cantilevers, with the two arms anchored on either side by twelve high tension steel wire hawsers running through galleries cut into the rock.

Essential to the span’s construction were two of Imbault's specially designed and very successful electric cranes, with two arms, each commanding a radius of 30 feet (9 metres) and able to revolve in an arc of nearly 180', and which handled the lifting and lowering of the steel sections into position. Capable of carrying 10 tons, these were arranged to stand on the cross girders and moved forward as each panel or 'bay' of twenty-five feet was completed. This stage was reached on the right bank early in December, 1904, and on the left bank during the last days of the same month. Hobson (1907): "The first panels, being the largest and containing the most material, naturally occupied the longest time, 2 to 3 weeks ; but this was gradually reduced until at the centre, eight posts and their fellow members were placed in position in 26 days, the work, of course, being done simultaneously from both sides of the river, so that each panel occupied 6 days in erection ; and this rapidity was attained in spite of delay caused by the delivery of the material failing to keep pace with the progress of the erection, which constitutes fair testimony not only to the efficiency of the design, but also to the precision achieved in the workmanship" [Hobson, 1907]

A team of about 30 skilled European engineers erected the steelwork, assisted by hundreds of local African labourers, being paid from 10 shillings to £3 per month, as many as 400 were employed at one period, although the average number during construction was about 200.

A safety net was slung on wire ropes stretched tight across the gorge and as close up to the arch as possible, about three hundred feet (90 metres) above the water. It is reported that on first seeing the safety net the African workforce went on strike as they thought they would be expected to leap into the net! Fortunately the net was never called into use other than to catch tools.

Completing the bridge

The building of the bridge progressed smoothly and on 1 April 1905 the main arch was linked. In the previous twenty-four working days some 500 tons of steelwork had been erected under great discomfort due to the spray from the falls falling at its greatest intensity during the Zambezi’s floods.

"The two centre panels of the arch were fixed about sunset on the 31st March, 4 months after the end posts had been erected, and it was found that the panels overlapped to the extent of about 1¼ inch. The steel truss had been exposed the whole of the day to the heat of the tropical sun and had elongated. When work was begun at sunrise next morning, it was found that it had contracted in the night to the extent of 1¼ inch." [Hobson, 1907] During the night, the wind had changed and blown the spray of the Falls on to the bridge, cooling and contracting the metal.

Varian again describes the processes involved in more detail: "All were assembled at dawn. Connecting plates were in position, and on each side of the lower booms men stood by with drifts and service bolts ready to catch the rivet holes as they coincided and came into position. For some unaccountable reason on that morning and at that hour, the wind changed. The usual spray failed to fall on the bridge, with the consequence that the steelwork was dry and ready to absorb the heat, which might spoil the chance of a junction being effected that day. The sun rose, and started to warm one side of the steelwork, which immediately began to expand, while the gap closed perceptibly from the expansion, the warm side faster than the cooler one. There was an anxious few minutes as we wondered whether the action of the winches on the steel cables would be in time to sway the whole body of the steelwork into the direct alignment before the fast-closing gap could forestall it. Then, slowly, with the action of expansion closing, and the winches swinging the joint laterally, they coincided to make a perfect butt joint. As soon as the rivet holes of the cover plate, some four feet square, and those of the boom coincided, drifts were immediately driven and service bolts made the joint fast, very much to the relief of all concerned." [Varian, 1953]

On completion of the top boom, two hydraulic rams were inserted in the centre, exerting between them a permanent pressure of 500 tons. The joint was then riveted and the jacks removed. The upper boom was successfully connected in June, and a temporary track was immediately laid over the open steel work.

By July all the steel work construction was complete, with the exception of the riveting. The original framework was originally connected with service bolts or pins, which were removed and replaced by rivets, but the riveting took far longer than was anticipated, due to a shortage of men with the experience.

The temporary track was strengthened for light traffic, and alongside was laid a footway eight feet in width, made of loose timbers laid on the open steelwork. Traffic operated at night, starting in the evening as soon as the bridge-hands had knocked off for the day. The first train to cross, limited at that stage to two wagons was the Jack Tar, which was then able to shunt materials between the southern construction yard and Pauling's Maramba Rail Depot on the northern side so that the rail line to Kalomo could progress whilst the bridge was completed. In fact, some 50 miles had already been constructed with materials taken over the gorge by the Blondin.

Official opening of the Victoria Falls Bridge

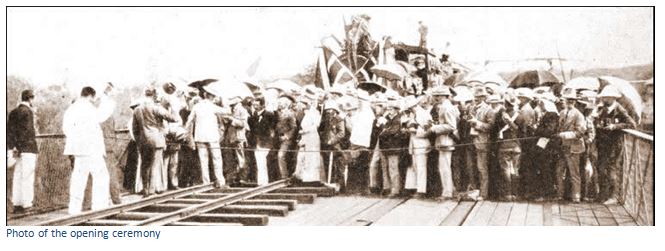

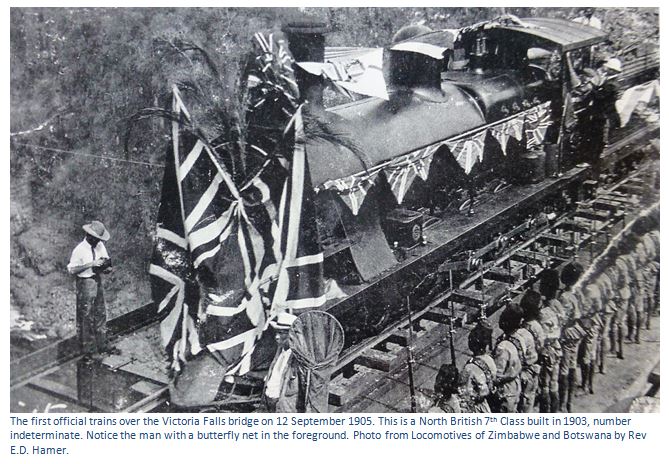

This took place on 12 September, 1905 with the residents of the Old Drift coming by boated from Geise's Drift and walking up to the end of the railway line where the last sleeper was to be laid.

One of the newest 7th Class engines in the country at the time, decorated with two the flags of the British South Africa Company and the Union Jack, palm leaves, flowers and other vegetation, pulled the six coaches and halted on the bridge for the passengers to alight, Mr Alan Martin Bowes was the driver of the train. The party was met by Robert Coryndon, the Administrator of North Western Rhodesia and Sir Charles Metcalfe made a welcoming speech and invited the astronomer Professor George H Darwin, son of Charles Darwin and President of the British Association (now the Royal Society), to declare the Victoria Falls Bridge officially open.

In all it had taken only nine weeks for the actual erection of the steelwork, with the whole construction extending over fourteen months. 1,868 tons of steel were used to make the bridge parts in Darlington, England, from where they were shipped 13,600 kilometres and fitted together on site. The bridge is 250 metres (820 feet) across, with a main arch spanning bridges graceful main arch is about 156.50 metres in length, at a height of 128 metres above the low water mark of the river in the gorge below and at the time it was built the Victoria Falls bridge was the highest above water level in the world.

Much of the above is abbreviated from P.Roberts Sun, Steel & Spray - A history of the Victoria Falls Bridge published by the Victoria Falls Bridge Company (2011) and appears in www.tothevictoriafalls.com

Acknowledgements

P. Roberts. Sun, Steel & Spray - A history of the Victoria Falls Bridge. Victoria Falls Bridge Company, 2011

Percy M. Clark. The Autobiography of an Old Drifter. Books of Rhodesia 1972

Hobson, G. The Victoria Falls Bridge. Institution of Civil Engineers, Session 1906-1907, Part IV, Section 1. Minutes of Proceedings 19 March, 1907 (Paper No 3675). Volume 170,January 1907, Pages 1–49.

H.F. Varian. Some African Milestones. Books of Rhodesia 1973