The Charles Burrell Steam Traction Engine / Road Locomotive

Bernard Francis Webber presented the National Archives with this Burrell Steam Traction Engine / Road Locomotive in January 1970.

As far as I know, there are only two surviving examples of Traction Engines / Road Locomotives in Zimbabwe; this Charles Burrell example from 1903 and the 1896 Bow McLachlan outside Mutare Museum.

The Mutare Museum also houses the 1903 Ivel Agricultural Motor No 141; one of only seven complete examples that still exist. [See articles on Mutare Museum under Manicaland on the website www.zimfieldguide.com]

There are some examples of portable steam engines that can power a sawmill, or maize sheller, but they are not self-propelled and need a team of draught oxen to move them, at Halfway House [See the article under Manicaland] and also at the Kadoma Steam Centre at Kadoma [See under Mashonaland West]

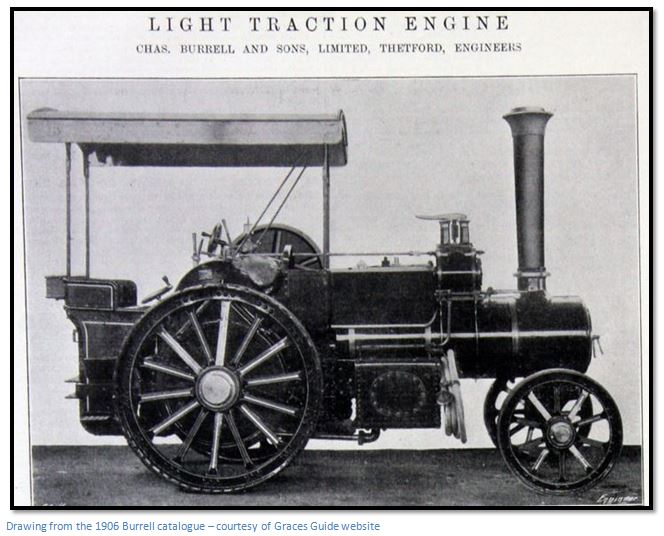

Charles Burrell and Sons of St. Nicholas Works, Thetford were producers of traction Engines, rollers and showman's Engines. Charles (grandson of the founder) was 20 when he took over in 1837, and was to see the name of Burrell become world-famous during his 69-year 'reign' to his death in 1906. Charles Burrell & Sons, steam and agricultural machinery manufacturers were the first to introduce a practical heavy-duty traction engine for use on roads and produced steamrollers and ploughing engines. More than 4,000 engines left the St Nicholas works during the life of the firm and were exported around the world; 329 are known to be preserved.

From the Borrowdale Road, turn into Churchill Avenue East as if going to Newlands, turn first right into Hiller Road signposted for the National Archives, turn right into Ruth Taylor Road, and turn left into National Archives at signpost.

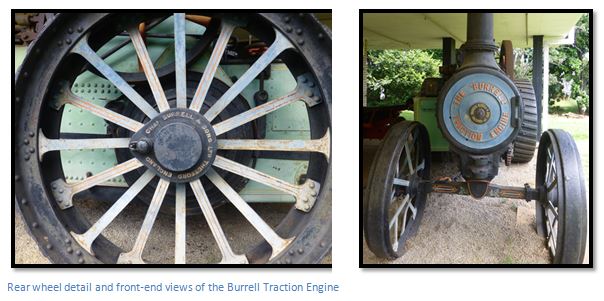

This eight horsepower single cylinder Engine No. 2554 was built by Charles Burrell and Sons of Thetford, England in 1903 and initially exported to Germany, but was in Rhodesia (now Zimbabwe) by 1913, as it has a Rhodesian boiler inspection stamp for that year. The engine worked in Salisbury as well as Shamva on transport work. It was later used to power a maize sheller and finally for producing steam for the tobacco barns on Gudubu Farm in Mhangura.

It is clear from photos of the Burrell traction engine being moved by low loader to the National Archives site, that the original chimney was much taller and folded down and was probably fitted with a spark arrestor to prevent bush fires; this has been rather crudely cut away so it would fit into the confined space. Colonial traction engines and portable engines were modified versions of those sold in the UK and Europe, as they needed to be wood burning rather than coal burning, as coal was largely unobtainable in Africa at the time. Earlier versions from 1896 have a steering chain connection to each end of the front axles; later versions (including this 1903 model) had a steering rod with a worm gear.

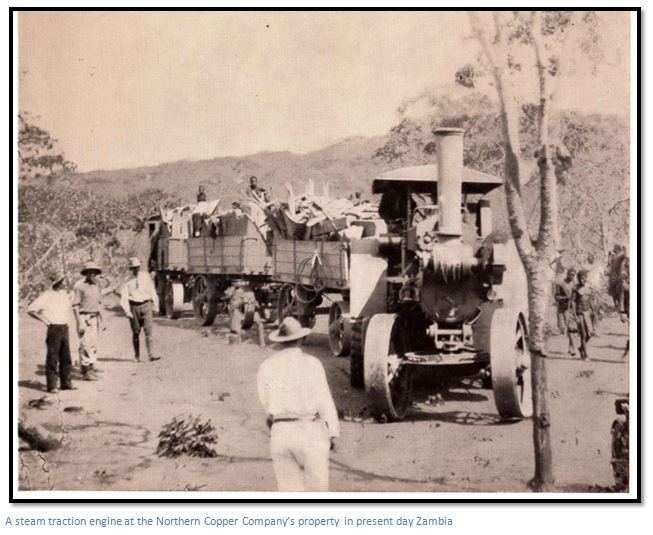

One of the first traction engines pulled ox-wagons across the Limpopo River, and was then used at the Globe and Phoenix gold Mine. There were believed to be at least four traction engines used to haul goods between Macequece (now Manica) and Umtali (now Mutare) with similar wagons to those shown below because all the draught oxen that had formerly hauled ox-wagons died during the rinderpest plague of 1896. Their usefulness in hauling wagons ended when the Beira and Mashonaland railway was completed.

A narrow gauge line was built by the Beira Railway Company (owned by the British South Africa Company) from Fontesvilla on the Pungue River, fifty-six kilometres from Beira, to Umtali, on Rhodesia’s eastern border. This line was begun in September 1892 with the Beira Junction Railway, connecting Fontesvilla with the port completed in October 1896. This line reached Umtali in February 1898 and had an initial gauge of only 2 ft., and needed to be quickly converted as the gauge of the line from Umtali to Salisbury, built by the Mashonaland Railway Company, and completed in May 1899, was 3 ft. 6 in.

In later years, traction engines played a notable part in the development of the country, particularly in areas where there was no railway and in tsetse fly regions. When their transport roles had become superceded, they remained useful for many years in a stationery capacity providing steam power on mines and farms.

Charles Burrell Steam Traction Engine specifications: |

| |

Cylinder base: | 9 inches | 22.9 cm |

Stroke: | 12 inches | 30.5 cm |

Steam working pressure: | 140 lbs / sq. in | 9.7 bar |

Boiler tested to 440 lbs / square inch |

|

|

Unladen weight | 9 tons 17 cwt 2qr | 9,889 kg |

Laden weight: | 11 tons 8 cwt 2qr | 11,431 kg |

Retail price: | about £420 |

|

The Charles Burrell Museum in Thetford is housed in the original paint shop of the Charles Burrell St Nicholas Works; a business that once employed 350 people and supplied traction engines, agricultural machinery, steam trucks, wagons and tram engines.

| A brief History of the firm of Chas Burrell & Sons | |

| 1793 | The company of Charles Burrell and Sons is generally regarded as being founded by Joseph Burrell (1759-1831), who in 1793 took over the whitesmith’s and blacksmith’s business of his father Benjamin (1725-1793). In partnership with his brothers William (1766-1832) and James (1770-1837), he turned the firm into a small engineering business. From repairing agricultural implements, they moved into making them. |

| 1803 | They first attracted notice at the annual Holkham Sheep Shearing they exhibited a seed and manure drill of James’s own design. The firm moved to the current St Nicholas Foundry site |

| 1804 | James filed a patent for an improved threshing machine. |

| 1805 | Showed a mowing machine at Holkham. |

| 1832 | James Burrell managed the business alone after his two brothers died, and on his death in 1837 control passed to his second son Charles Burrell (1817-1906), aged only 20. Charles turned what was a modest country engineering firm into one of the leading agricultural and steam engineers of the nineteenth century. |

| 1837 | He changed the name of the business to Charles Burrell, engineers and agricultural machinists, and this later became Charles Burrell and Sons, as his sons Charles (1847-1929), Robert (1849-1904) and Frederick (1865-1927) became actively involved in the 1870s. |

| 1846 | Charles Burrell was one of the first firms to make portable steam engines. |

| 1848 | The company produced the first combined threshing and dressing machine which soon became the standard for all except the smallest machines. |

| 1851 | Exhibited at the 1851 Great Exhibition winning an award. By now the company employed 52 men and 11 boys. |

| 1850's | Charles Burrell concentrated his technical abilities on the development of self-moving steam engines collaborating with James Boydell, patentee of an ‘endless railway’ mechanism. This consisted of a series of flat feet attached to the outside of the engine's wheels. They were hinged in such a way that as the wheel revolved each succeeding foot would lie flat in contact with the ground, thus spreading the weight of the engine. The idea was that this arrangement would be more efficient for road-haulage engines, enabling them to deal with poor road surfaces and in 1855 Burrell became the licensed manufacturer of Boydell engines. |

| 1856 - 1862 | They made several types of Boydell engines for use on the roads and for ploughing by direct traction, but they proved unsuccessful, both technically and commercially, and Burrell turned instead to the development of conventional wheeled traction engines. In this he had considerable achievements, and his firm came to be known mainly for its traction engines and road locomotives. |

| 1862 | Exhibited at the 1862 London Exhibition. |

| 1870's | Charles Burrell was working with Robert William Thomson in the production of his road steamers, steam tractors designed to haul passenger and goods vehicles on the roads and the company was employing 180 men and 10 boys. |

| 1877 | Exhibitors at the 1877 Royal Agricultural Show at Liverpool. |

| 1882 | A Portable Engine, designed by Frederick Burrell was exhibited at 1882 Royal Agricultural Show. |

| 1884 | The business was incorporated as Charles Burrell and Sons Ltd. Charles Burrell was chairman, although by now he was not so actively engaged in day-to-day management. Under his leadership the firm grew from one employing about 200 in 1870 to 400 in 1913, comfortably the largest employer in Thetford. The firm established a good reputation for its traction engines and steam road locomotives, especially with travelling showmen. It also entered electrical engineering. |

| 1886 | Making steam tram engines which went to Birmingham and Bradford. |

| 1889 | Exhibited a horizontal engine shown at the RASE show at Windsor. Patented a compound engine with a final production of over 1,000 made |

| 1890 | Produced a 20 hp semi-portable compound engine. |

| 1894 | produced a 10 hp compound Traction Engine. |

| 1904 | Charles Burrell retired completely, and was succeeded as Chairman of the company by his eldest son Charles Burrell (1847-1929), one of three sons who entered actively into the business in the 1870's. |

| 1907 | Won the Gold Medal in the RAC Trials for a five-ton steam motor tractor. |

| 1911 | Exhibited an agricultural locomotive and a steam tractor at the Smithfield Club Show. |

| 1919 | After the First World War the business was taken into the Agricultural and General Engineers combine (AGE) and Charles Burrell retired as chairman. |

| 1920 | Exhibited a steam road locomotive at the Darlington Agricultural Show. |

| 1928 | The goodwill, drawings and patterns were transferred to Richard Garrett and Sons. |

| 1929 | Manufacture at Thetford ceases. Charles Burrell dies. |

| 1932 | AGE was wound up |

Acknowledgements

National Archives of Zimbabwe

Charles Burrell Museum

Graces Guide